The electronics world is advancing quickly, and the role of circuit boards, specifically flexible printed circuit boards (PCBs), is coming to be increasingly important throughout various applications. Among these, HDI (high-density interconnect) PCBs and RF (radio frequency) circuit boards stand out for their specialized usages, particularly in compact and high-performance electronic devices.

Flexible PCBs are changing exactly how we think concerning circuit design. Unlike traditional rigid boards, flexible PCBs are bendable and can be molded to fit into complex geometries, allowing for greater flexibility in digital item design.

Megtron 6 is an example of a material that has catapulted flexible PCBs into greater efficiency worlds. This material's residential or commercial properties are particularly advantageous for HDI PCBs, which need dependable efficiency even in portable, multi-layered designs.

The advancement of HDI technology has been a game-changer for the electronic devices market. By lowering the area required for interconnections and boosting the density of elements on a board, HDI PCBs deal with the need for smaller, lighter, and extra powerful electronic gadgets. They include attributes like blind vias, which connect different layers of a board without passing via the whole board, enhancing the room used for connections and decreasing overall dimension and weight. These features make HDI PCBs positive for cutting-edge applications like mobile phones, wearables, and high-performance computer tools.

Likewise, RF circuit boards have actually become crucial parts in cordless communication gadgets. As the promote faster and a lot more trusted cordless communication grows, so does the demand for RF PCBs. These circuit boards are customized to take care of high-frequency signals and call for accurate manufacturing processes to preserve signal integrity and stay clear of disturbance. RF boards are indispensable in systems varying from satellite communications to customer wireless innovation, where performance and dependability can not be compromised.

The manufacturing procedures and assembly of these PCBs are critical to their capability and dependability. Top notch assembly solutions are required to place small parts accurately on the boards, especially for flexible and HDI PCBs, where component density is high. This procedure, commonly performed by specialized PCB assemblers, requires advanced equipment and experienced professionals to make certain that every connection fulfills exacting requirements.

Fast turn PCB solutions mirror the speed-oriented demands of modern-day electronic devices markets, stressing the demand for quick prototyping and manufacturing to stay on par with technical innovations and market trends. These services are necessary for business needing to check layouts rapidly and bring advancements to market with very little delay. Additionally, selecting a reliable flex PCB manufacturer can heavily affect the result in terms of cost-effectiveness, performance, and longevity, as these makers use personalizations and enhanced production procedures satisfying specific customer needs.

Technology in PCB board assembly has advanced, with automated production line enhancing accuracy and effectiveness. The need for greater precision and fast turn-around times has actually sped up the fostering of automated methods and ingenious soldering methods to satisfy intricate assembly challenges. This elegance in assembly not just improves the performance of PCBs but likewise guarantees their durability and reliability.

Printed circuit board assembly (PCBA) is one more essential area, where several parts like resistors, capacitors, and ICs are mounted on the PCB. Each part includes performance and plays a crucial function in the circuit's habits. Advancements in this location consist of using sophisticated substrates and eco pleasant materials that line up with worldwide sustainability trends without giving up efficiency.

For RF circuits specifically, precise engineering is vital in preventing signal loss and distortion, straight influencing the efficiency of the interaction devices. The challenge exists in the product selection and design format, which must lessen disturbance and keep consistent efficiency across various operating conditions. Skilled engineers must work together with knowledgeable PCB makers and assemblers to attain optimum outcomes.

Rigid-flex circuit technology integrates the most effective of both flexible and rigid PCB qualities, giving durable options that include flexible components into a rigid framework. This crossbreed style is indispensable in applications calling for both toughness and adaptability, like aerospace and armed forces options, where wiring needs to comply with unique shapes without giving up sturdiness or capability.

The interconnectivity landscape is regularly developing, and high-density interconnect PCB innovation proceeds to push the limits of what is possible with contemporary electronic devices. The raising range of assimilation within little form variables permits even more capability within a single tool while preserving efficiency, decreasing expenses gradually. As we look towards the future, the interaction in between products scientific research and electrical design in the advancement of these innovative circuit boards guarantees to produce a lot here more ingenious options that will certainly form our technical community.

Flexible PCBs are changing how we believe concerning circuit style. Unlike traditional rigid boards, flexible PCBs are bendable and can be molded to fit right into complex geometries, permitting for better freedom in electronic item style.

Megtron 6 is an example of a material that has actually catapulted flexible PCBs right into better efficiency worlds. This product's homes are particularly valuable for HDI PCBs, which call for dependable efficiency even in small, multi-layered layouts.

By decreasing the area required for affiliations and raising the density of parts on a board, HDI PCBs provide to the demand for smaller sized, lighter, and much more effective digital gadgets. These functions make HDI PCBs favorable for cutting-edge applications like smart devices, wearables, and high-performance computing tools.

Finally, the digital industry's recurring fascination with producing smaller sized, extra powerful, and extra reliable gadgets drives the continued development and application of advanced motherboard innovations like flexible PCBs, HDI PCBs, and RF motherboard. With continued research study and a dedication to quality and advancement, the future of electronic devices assures to be intense and loaded with unprecedented opportunities and improvements. These innovations will certainly remain to allow the future generation of digital gadgets, making them a lot more easily accessible and qualified to meet the varied needs of customers worldwide.

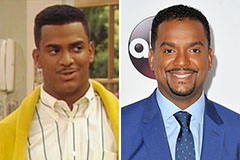

Alfonso Ribeiro Then & Now!

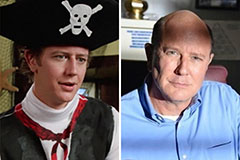

Alfonso Ribeiro Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Lucy Lawless Then & Now!

Lucy Lawless Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!